The successful application of inverter in the boiler blower of Herz

Design of variable frequency speed regulation system of industrial boiler combustion process,

According to the different industrial boiler fuel, usually divided into coal, oil and gas three. Basically the same combustion process control system of the three boilers, fuel quantity adjusting means is different. In automatic control process of various civil, industrial boiler, automatic control of boiler combustion process is an important content of control. Traditional control scheme, drum, induced draft fan air volume generally use the damper control, grate motor and powder feeder with slip speed, its drawback is that regulation is not timely, complicated operation, cannot ensure the optimal operation state of boiler, waste of energy. In the process of industrial boiler combustion to realize inverter is mainly regulated by frequency converter blower air supply, induced draft fan air flow and fuel feed.

1.2 induced draft fan and blower operation mode

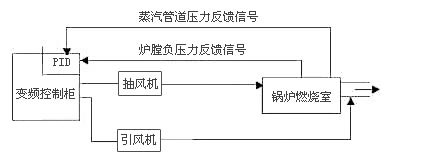

(1) wind control: through the negative pressure transmitter furnace on the feedback channel standard signals pressure furnace into fan inverter PID controller, after treatment, and compared the furnace negative pressure setting, the PID controller generates the operation signal, induced draft fan inverter adjusting motor speed control signal, so that the stable negative pressure in furnace in the set value, so as to achieve the automatic tracking of blast furnace pressure to maintain a constant. Fan motor speed varies with the furnace negative pressure value. To ensure that the boiler combustion automatic operation part.

(2) the blast control: the pressure transmitter steam pipe will be required for steam pressure standard electrical signals into blast inverter PID controller feedback channel, after treatment, and compared with the set of steam pressure, through the PID controller generates the operation signal, this signal control blast inverter control motor speed, so that the pressure steam pipe is basically stable at the set value, so as to achieve automatic tracking pressure steam pipe.

(3) due to the non energy saving boiler combustion control by manual operation, air duct baffle, steam pressure controlled burning is not alone

Good. Therefore, the motor running at full speed the flow can't all use, the baffle plate cut-off power loss caused about 30%. The use of frequency converter according to the production demand adjust the motor speed, so that the output flow can be adjusted, improve production efficiency and energy saving.

Two, speed:

1 operating workers on production by external remote acceleration / deceleration buttons to control the motor speed.

2 through the inverter terminal BICO connected to an automatic PID operation mode switch.

3 system can achieve full open loop operation, the control cabinet or site operation box on the start stop button and Realization of artificial control and speed control potentiometer.

The main chain, system three:

1 operating conditions: only when the blower fan running, blower was allowed to start running.

2 frequency and power frequency chain. Frequency operation and its working frequency, interlock control system.

3 when the frequency of the system fails during operation, sound, light alarm signal to remind the staff on duty, timely treatment.

Four, system structure:

Control system of 1 boiler reform

Configuration: the control cabinet

Blower frequency conversion power: RF300-011G-4; fan frequency conversion power: RF300-030G-4

The 2.RF300 control principle diagram

Five, frequency conversion control cabinet technical parameters and performance characteristics:

1 technical parameters and use environment:

The capacity of the boiler (1): 2 ~ 220t/h;

(2) variable frequency range: 0 ~ 60hz;

(3) for motor power range: 11kw ~ 280kw;

(4): control accuracy of ± 1%;

(5) the working voltage: 380V ± 10%;

(6) the environment temperature: -10 ℃ ~ 50 ℃;

The relative humidity of the air (7): less than 90%rh, no condensation;

(8) arranged places: no violent vibration, shock, no conductive gas or dust.

The performance characteristics of the 2 systems:

(1) with operation mode selection switch: to realize the frequency and power frequency locking, frequency operation for the original control system, frequency and power by converting switch, and has interlocking protection function.

(2) with frequency conversion mode of local / remote - selection switch: local artificial speed control potentiometer. Inverter PID control mode.

(3) variable frequency soft start: motor through the inverter starting, the motor voltage automatic digital slope compensation technique is adopted, the motor to speed up system mechanical impact is small, can significantly extend the control elements and fan service life of machinery.

(4) with complete motor and inverter, self protection function: the motor voltage, overvoltage, overcurrent, regeneration of overload, short circuit, over temperature protection.

(5) display has the function of power supply voltage, electric current cabinet instrument. The working state of inverter indicator function. And the frequency converter speed and operation of the motor current to 0 20mA standard analog form is transmitted to the DCS control system.

(6) converter failure alarm indication and transmission switching, remote reset function.

Six main debugging, parameter of the frequency converter:

P0.08

The acceleration time

P0.09

Deceleration time

P0.05

The upper limit frequency

P1.05

Shutdown mode

P0.00

Control mode

P0.03

Frequency setting method

Seven, the conclusion

The system from the design, equipment selection, installation and commissioning to operation, completed in a short time, good results, achieved the expected goals of users, running two years without failure, by users, create great economic benefits for the enterprise, has great value of popularization.

六、变频器的主要调试参数:

|

P0.08 |

|

|

P0.09 |

|

|

P0.05 |

|

|

P1.05 |

|

|

P0.00 |

|

|

P0.03 |

|